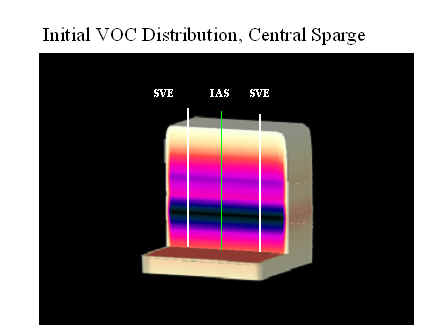

IAS works by forcing vapor flow through the aquifer and collecting

volatile contaminants in the vapor stream as it passes through

contaminated zones. IAS

also adds oxygen to the system, which can enhance biodegradation of

amenable compounds.

Unlike most other remediation methods, IAS generates flow gradients away

from the center of contaminant mass. It can also mobilize free and

trapped contaminant oils (NAPL) and push them to new locations.

These attributes can cause rapid and deleterious effects to surrounding

buildings, people, and other receptors. Therefore, the utmost care

in planning and design is necessary for this remediation method.

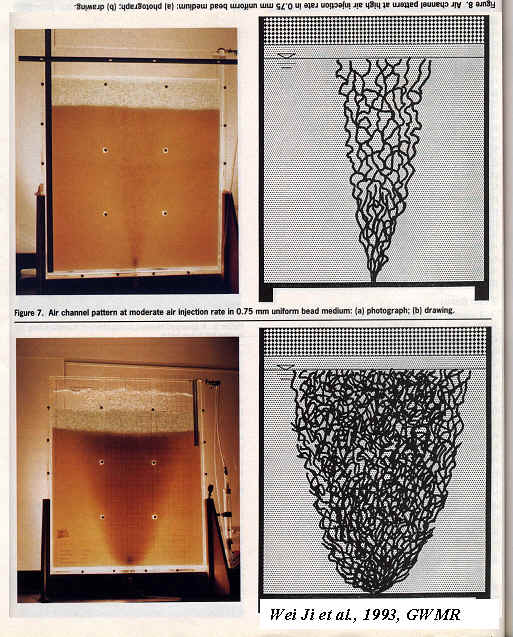

For most in the industry, IAS has been designed using a field parameter

called the radius of influence. ROI is a real measurement, but by

itself has very little to do with the effectiveness of IAS or lack

thereof. Similarly, SVE is typically used to capture fugitive

vapors from IAS, and it needs to be designed on a flow basis, not an ROI

basis. Flow rates and paths relative to the target contamination and

where IAS exits the water table are the key attributes to successful

sparging design. Because both air and NAPLs are non-wetting fluids,

design synergies exist for sparging that are rarely recognized by most

practitioners.

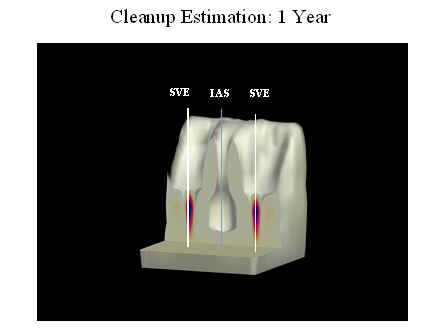

An efficient IAS design will collect more contaminant mass in less time

and at less cost than a system designed by ROI methods. Both

well-designed and poorly designed systems will go asymptotic, but the

well-designed system leaves much less residual contamination and therefore

greatly reduces the risk and potential liability. Poorly designed

systems often leave zones of original contamination untouched, and

therefore provide no real value because the risk & liability are

unchanged.

Contact AVI for more details and examples of our applied approaches for designing & optimizing IAS systems, as well as defining endpoints of cleanup.